Rhode Island Convention Center

1 Sabin Street

PVD, RI

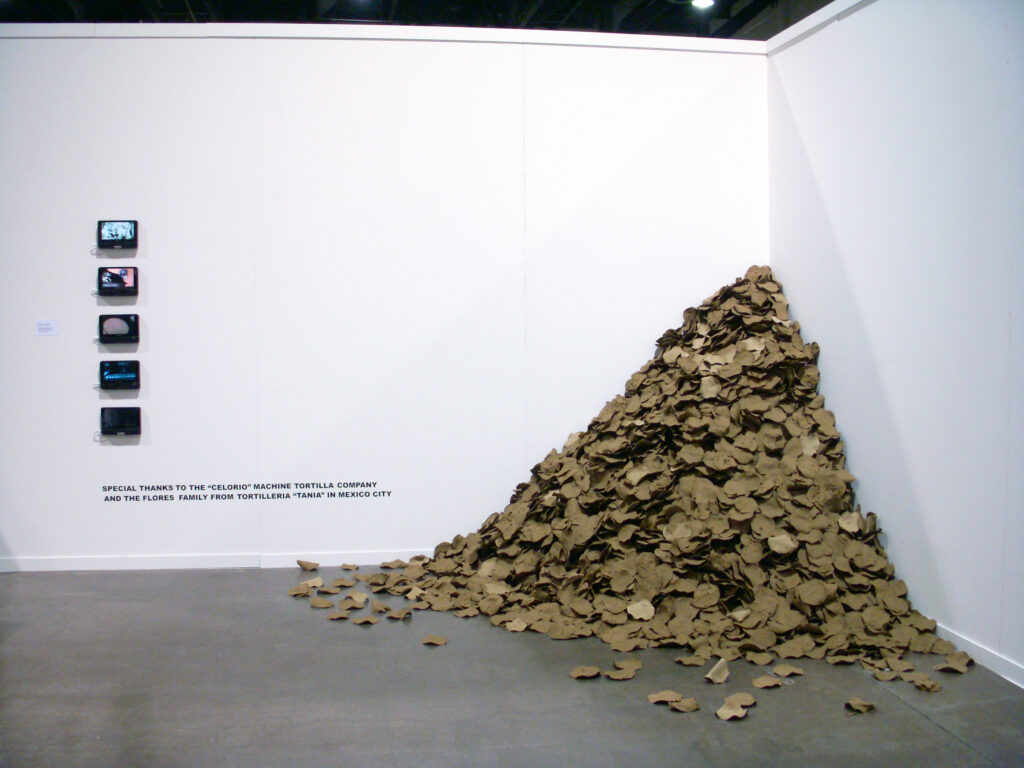

[Clay and corn tortillas, Celorio Tortilla Machine, video documentation (3 min.)]

A tortilla machine is a beautiful thing to watch, every Mexican has memories of the sound, the smell and the movement of these mechanical devices. To me it was a delight to go to the torillería after school. This meant I had to wait in line for fresh baked tortillas piling up in front of my eyes. A small salt cellar lingered by the weight scale, and after they were placed on paper, I could take one tortilla, put salt and roll it with both of my hands. A salt taco, the most basic identifiable particle of mexicanity: nationalism at its best.

The tortilladora technology, also came from the ‘ground’ as a response for a Mexican demand as opposed to receiving a foreign technology adapted for our environment. It was actually a grass-root solution for the efficiency of a hand-made process that was heroically undertaken by women under periods of 35 to 40 hours each week.

This technology had some resistance, in a book review of Technological Mestizajes and Cultural changes in Mexico written by Charlotte M. Gradie, she synthesizes [Arnold] Bauer’s ideas expressed in his chapter:

“European technology was not adapted to the production of tortillas, a fundamental element in the native diet, a failure considered by Arnold Bauer. He compares the cultivation and processing of European cereals with maize and observes that while corn requires less time and energy to cultivate than wheat, oats, or barley, it is much more time consuming to process. Tortilla production fell to women and required five to six hours per day. Bauer concludes that the slow acceptance of mechanical grinding wheels in tortilla production is related to the low social status of native women and the desire of men to limit women’s independence” (Gradie, C., 2008).

Did technological efficiency change women’s lives beyond men’s desires to keep them in the kitchen? Maybe it was the Mexican Revolution along the technological advancements that created the perfect scenario for change. For me, this project was about technological migration and how these technologies provide a space for cultural resistance and resilience to those who migrate from any Latin American country.

6000 Clay and Corn Tortillas Made by a Celorio Tortilla Machine is a two-phase project that took place in 2009. On Phase I, tests were made at the Inventions Department in the Celorio Tortilla Machine plant where a mixture of clay and corn was inserted into the tortilla machine.

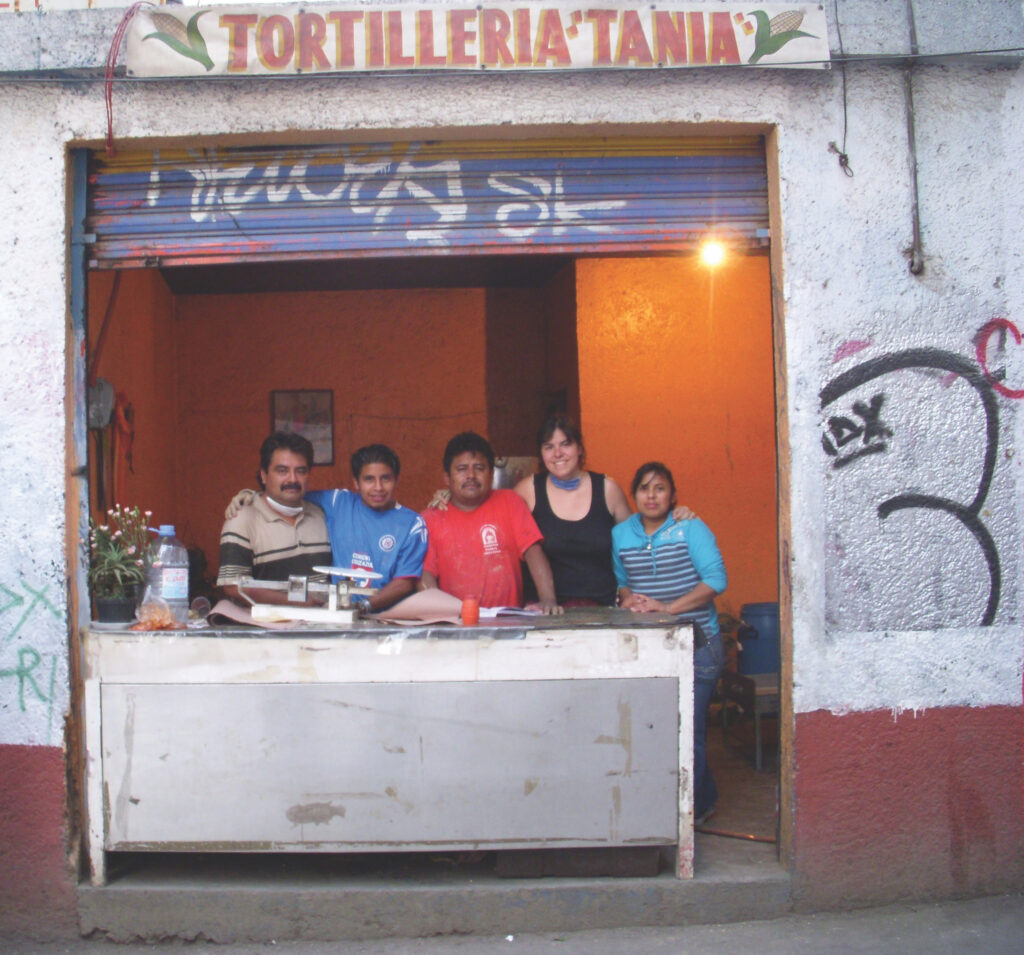

Phase II consisted of replicating the process at a commercial tortilleria in Mexico City where 3000 clay and corn tortillas were produced, and a later batch of 3000 pieces were produced and shipped to Providence, RI for installation.

RISD Feed Interview

Special Thanks to Mercedes Castañeda, Camerino Osorio Osorio and Erasmo Leonides from the Celorio Tortilla Machine and Joel Flores and his family, owners of Tortilleria Little Star.